-

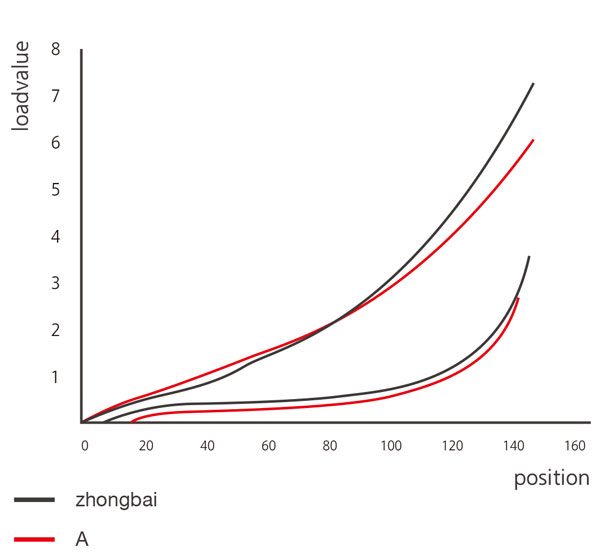

ZhongbaiZhongbai high-elastic spandex is specially designed to combine high resilience with high strength, giving the fabric a perfect resilience spandex.

ZhongbaiZhongbai high-elastic spandex is specially designed to combine high resilience with high strength, giving the fabric a perfect resilience spandex.

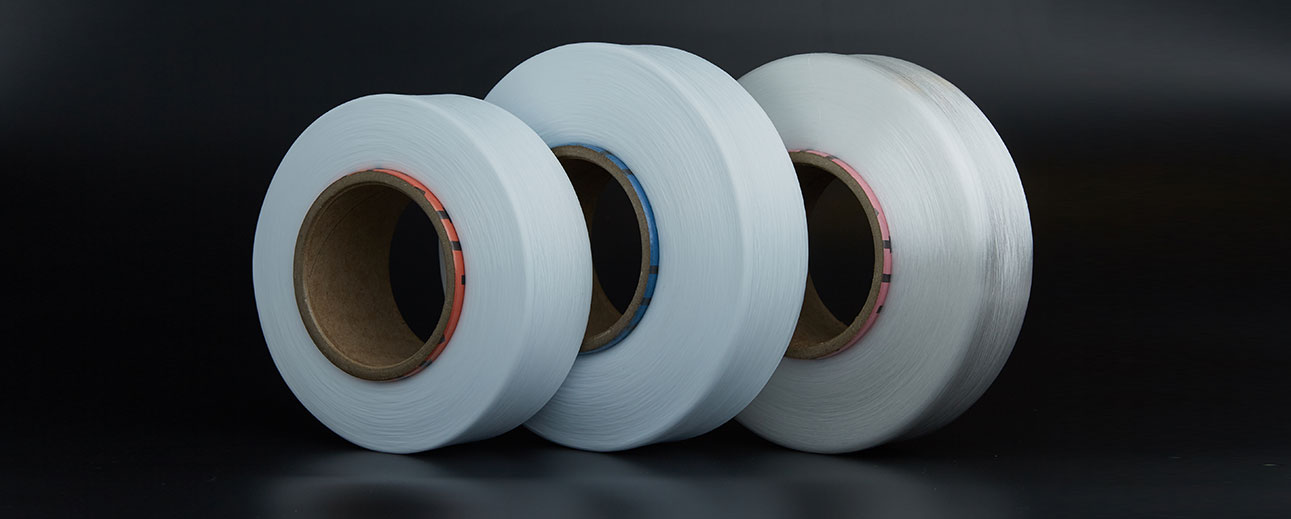

The specifications of spandex spandex are 20D, 30D, 40D, 70D and 105D.

Matters needing attention in product processing

Matters needing attention in product processing

1. The environment temperature and humidity have great influence on the processing performance. The optimum temperature is 25 3, and the relative humidity is 65.5%.

2. Pay attention to the type, specification, batch number and the color of the paper tube on the list when using the product. It is forbidden to use mixed batch.

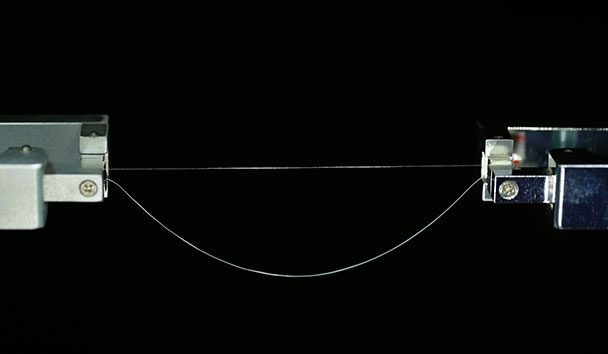

3. Drawing ratio of the product will affect the process of fabric and the uniformity of the fabric. When the drawing ratio is too large, the processing and weaving will break easily, resulting in the reduction of processing efficiency and product quality.

4. The production date interval of the product will affect the homogeneity of the process and the fabric. It is suggested that the products with adjacent production dates should be used, and the silk rolls used in weaving are similar in size.

5. In circular weaving, the conveying tension of the product should be appropriate. The excessive conveying tension can easily cause wire breakage, and the excessive conveying tension can easily cause the conveying roller to spring up and cause the weaving to stop.